Hello, I'm

Himal Sapkota

Mechanical Engineer

Hello, I'm

Mechanical Engineer

I am an enthusiastic Mechanical Engineer with a vision to revolutionize the way we design and manufacture products. In a world where efficiency and sustainability are more important than ever, I am passionate about leveraging additive manufacturing and AI-driven technologies to create smarter, faster, and more sustainable solutions.

Currently pursuing my Master of Science in Mechanical Engineering at Southern Illinois University Carbondale, I am actively working as a Research Assistant, specializing in metal additive manufacturing. My research integrates nondestructive evaluation (NDE) and machine learning/deep learning to optimize manufacturing processes and minimize material waste. My academic journey began with a Bachelor’s degree in Mechanical Engineering from Tribhuvan University, Nepal, where I laid the foundation for my passion for innovation and problem-solving.

Eager to contribute to pioneering projects, I bring a unique combination of technical expertise, data-driven problem-solving, innovative thinking, and collaborative leadership to the field of Mechanical Engineering. Welcome to my portfolio—a space where expertise meets an unwavering commitment to engineering excellence and innovation.

Carbondale, Illinois

Aug 2025 - Present

Jan 2023 - May 2025

Notable Coursework: Fundamentals of CAD/CAM, Advanced Manufacturing and Sustainability, Reliability Analysis, Additive Manufacturing, Non-destructive Testing and Evaluation of Material (NDE), Deep Learning, Experimental Design, X-ray Diffraction

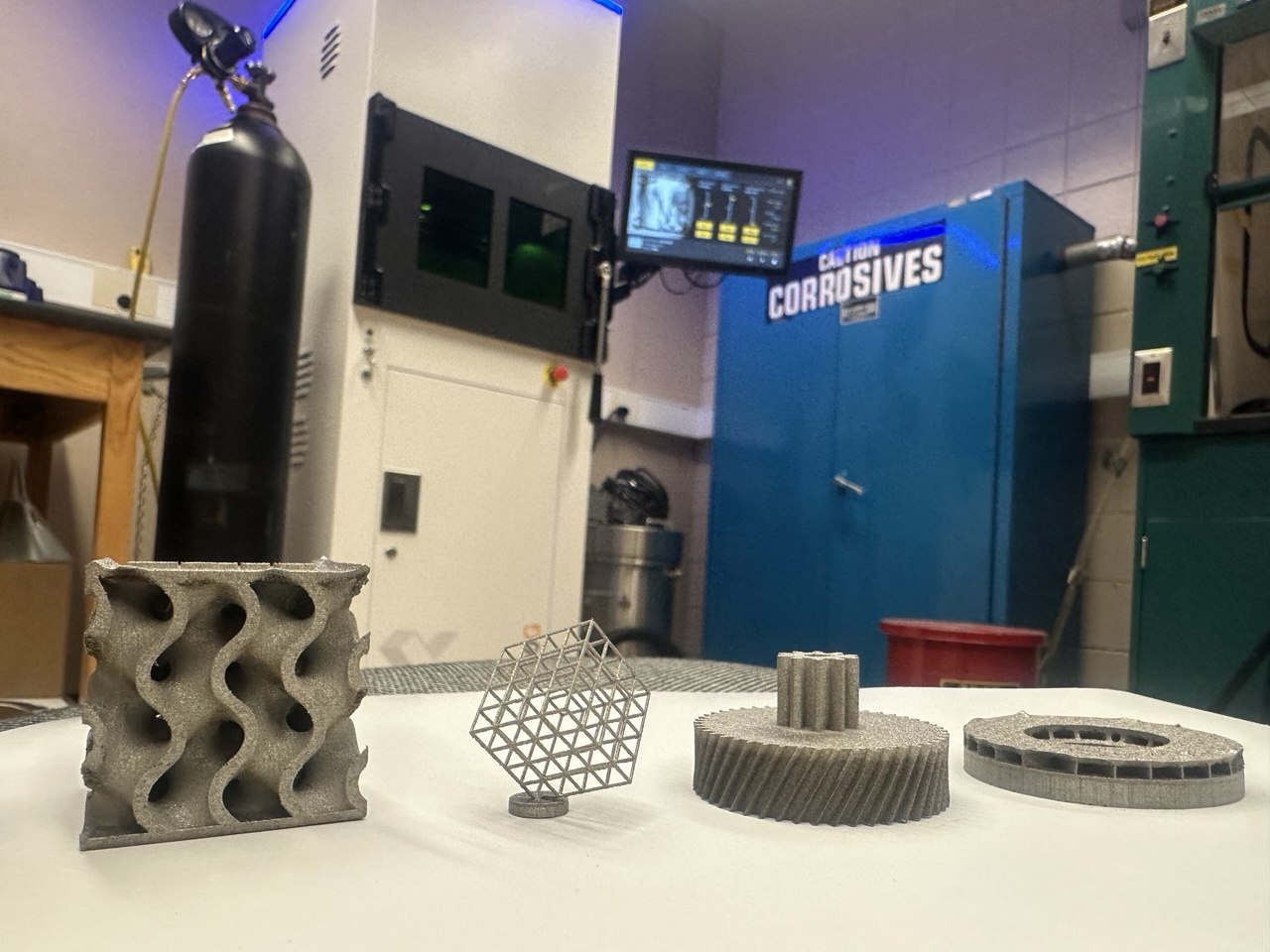

Research Areas: Metal Additive Manufacturing (MAM), Topology Optimization (TO), Design for Additive Manufacturing (DfAM), Defect Detection, Application of Machine Learning/Deep Learning in AM, NDE in Additive Manufacturing

Dharan, Nepal

Nov 2013 - Aug 2017

Significant Courses: Electrical Machine, Strength of Materials, Manufacturing and Production Process, Fluid Mechanics, Instrumentation & Measurement, Control System, Mechanics of Solid, Heat Transfer, Fluid Machines, Probability & Statistics, Machine Design, Theory of Mechanism & Machine, Turbo Machines, Finite Element Method, IC Engine, Energy Resources, Industrial Engineering & Management, Automobile Technology, Engineering Economics, Project Engineering and Management, and Quality Management

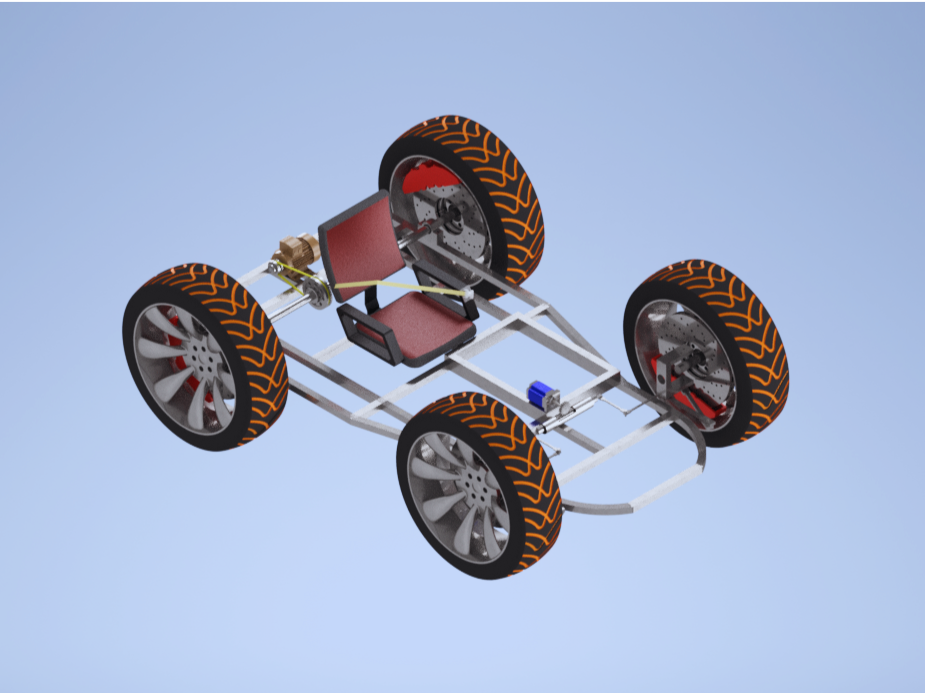

Final Year Project: Study and Fabrication of Prototype of Regenerative Braking System

Aug 2023 - Present

Carbondale, Illinois

Designed and optimized 3D CAD models and fabricated prototypes for additive manufacturing.

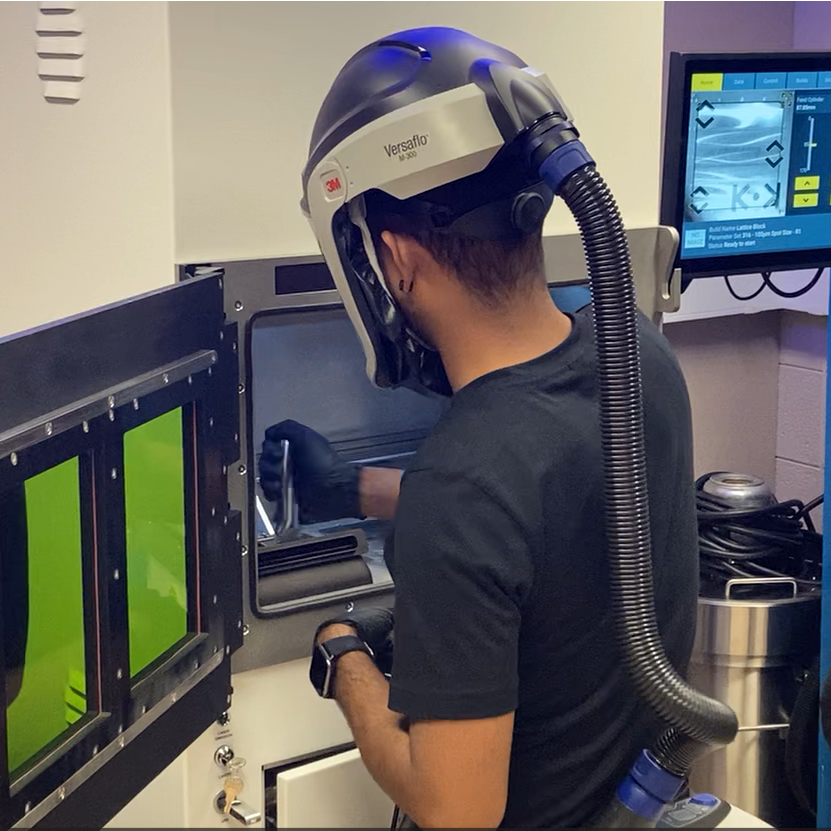

Served as Lab Manager for the Advanced Manufacturing and Design Lab, managing operations, maintenance, troubleshooting of XM 200G laser powder bed fusion 3D printer and mentoring lab colleagues.

Led the project for material parameter development of stainless steel powders utilizing Design of Experiments (DOEs), optimizing printer parameters to achieve over 99.5% wrought density in final 3D printed parts.

Performed Failure Mode and Effects Analysis (FMEA) and Root Cause Analysis (RCA) to identify and mitigate mechanical failures (porosity, warping, delamination) in metal additive manufacturing.

Collected and analyzed engineering data for inspection from X-ray Computed Tomography (XCT), mechanical tests, and CAD simulations to correlate printing process parameters with geometric deviations and defects.

Documented fabrication workflows for metal additive manufacturing, including control plans, inspection protocols, and preventive maintenance schedules, ensuring compliance with OSHA standards.

Jan 2023 - Dec 2024

Carbondale, Illinois

Conducted lab experiments to over 150 students, evaluated lab reports, and graded assignments for the courses: Engineering Heat Transfer, Applied Fluid Dynamics, Materials Science Fundamentals, Measurement and Instrumentation, and Aircraft Flight Dynamics.

May 2019 - Nov 2022

Biratnagar, Nepal

Managed engineering projects for agricultural machinery maintenance and troubleshooting, optimizing preventive maintenance strategies and reducing downtime by 10%.

Investigated mechanical failures and performed RCA to address failures, increasing annual maintenance contracts by 15%.

Implemented Just-In-Time (JIT) inventory management strategies to streamline processes and reduce downtime.

Served as primary liaison for customer relationship management, ensuring high customer satisfaction and retention and created detailed engineering reports and assessments, ensuring compliance with industry standards.

Aug 2017 - Mar 2019

Sindhuli, Nepal

Oversaw the activities of 26 faculty and staff members, ensuring high instructional standards and mentoring teachers to improve student performance.

Assisted students in 2D/3D mechanical drawings using AutoCAD and guided them in sheet metal and fabrication processes.

Oct 2016 - Dec 2016

Kathmandu, Nepal

Assisted in troubleshooting and optimizing performance of TATA's light commercial vehicles (LCVs) and heavy commercial vehicles (HCVs), ensuring vehicles met TATA standards for safety and efficiency.

Collaborated with the service team to implement preventive maintenance schedules, reducing the likelihood of mechanical failures in serviced vehicles.

Developed technical reports detailing vehicle performance metrics, repair processes, and improvements for service records.

Explore My